Construction and specification

|

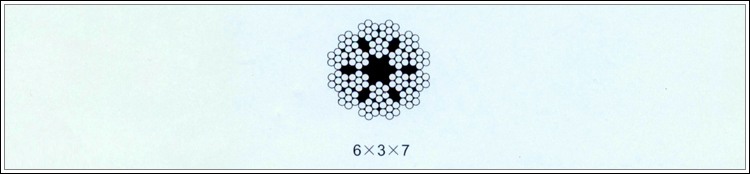

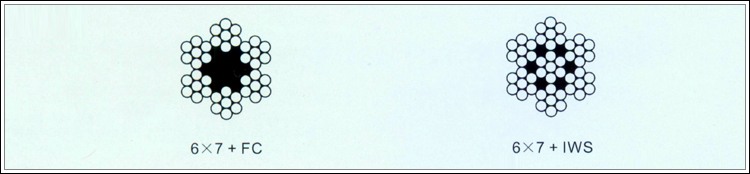

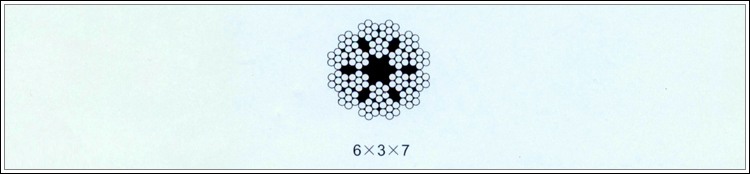

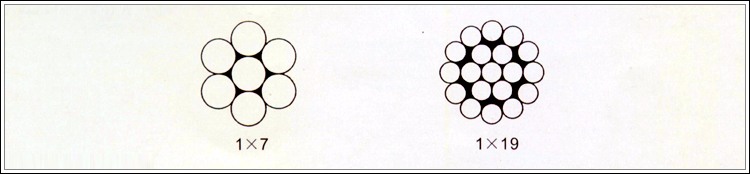

In the above example, each individual wire is arranges around

a central wire to form a 7-wire strand. Six of these strands are

formed around a central core to make a wire rope. The rope is

specified as 6x7 (6/1) – i.e. six strands each of seven wires. |

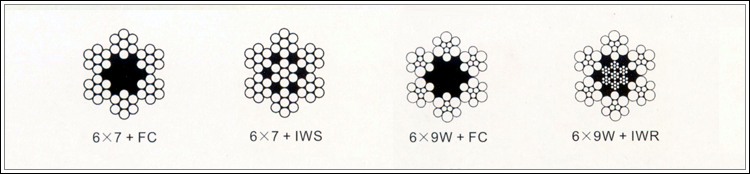

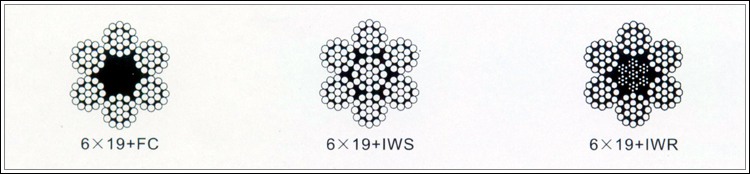

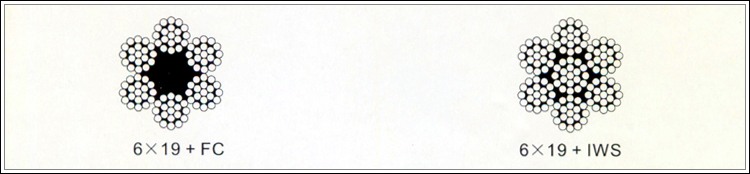

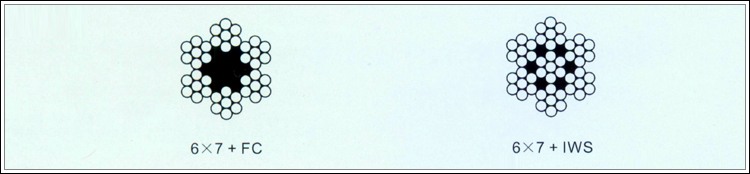

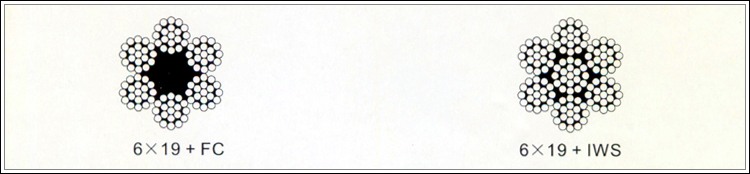

The specification of a wire rope type – including the number of wires per strand, the number of

strands, and the lay of the rope is documented using a commonly accepted coding system,

consisting of a number of abbreviations. This is easily demonstrated with a simple example. The

rope shown in the figure "Wire rope construction" is designated,thus:6x19 FC RH OL FSWR

| 6 |

Number of strands that make up the rope |

| 19 |

Number of wires that make up each strand |

| FC |

Fibre core |

| RH |

Right hand lay |

| OL |

Ordinary lay |

| FSWR |

Flexible steel wire rope |

Each of the sections of the wire rope designation described above is variable. There are therefore a

large number of combinations of wire rope that can be specified in this manner. The following

abbreviations are commonly used to specify a wire rope.

| Abbr. |

Description |

| FC |

Fibre core |

| FSWR |

Flexible steel wire rope |

| FW |

Filler wire |

| IWR |

Independent wire rope |

| IWRC |

Independent wire rope core |

| J |

Jute (fibre) |

| LH |

Left hand lay |

| LL |

Lang's lay |

| NR |

Non-rotating |

| OL |

Ordinary lay |

| RH |

Right hand lay |

| S |

Seale |

| SF |

Seale filler wire |

| SW |

Seale Warrington |

| SWL |

Safe working load |

| TS |

Triangular strand |

| W |

Warrington |

| WF |

Warriflex |

| WLL |

Working load limit |

| WS |

Warrington Seale |

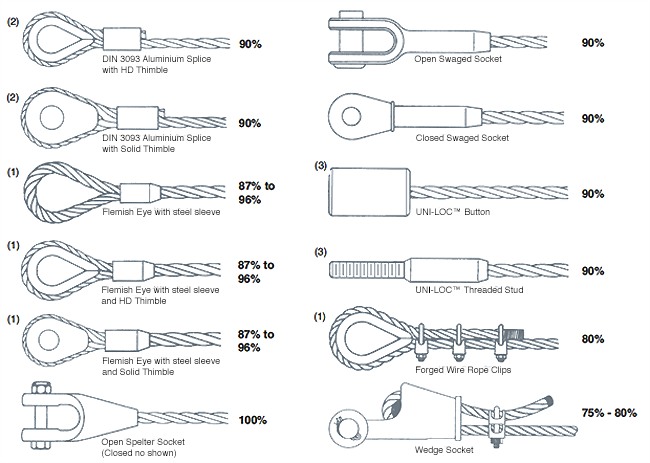

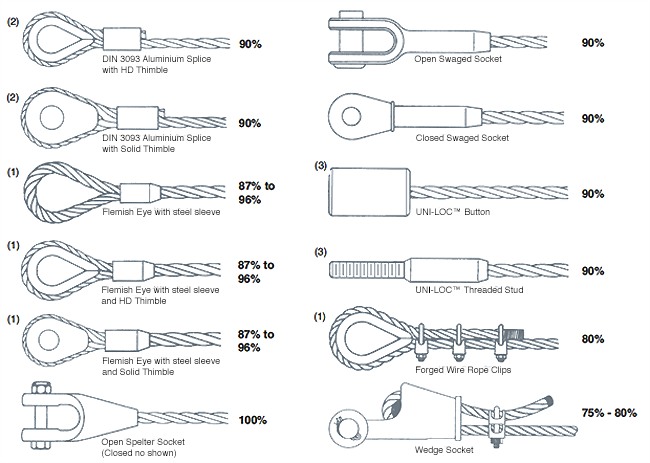

Termination available and Efficiency Ratings of Different End Terminations on wire rope

RHOL wire rope terminated in a loop with a thimble and talurit splice

The end of a wire rope tends to fray readily, and cannot be easily connected to plant and equipment.

A number of different mechanisms exist to secure the ends of wire ropes to make them more useful.

The most common and useful type of end fitting for a wire rope is when the end is turned back to

form a loop. The loose end is then fixed by any number of methods back to the wire rope.

Thimbles

When the wire rope is terminated with a loop, there is a risk that the wire rope can bend too tightly,

especially when the loop is connected to a device that spreads the load over a relatively small area.

A thimble can be installed inside the loop to preserve the natural shape of the loop, and protect the

cable from pinching and abrasion on the inside of the loop. The use of thimbles in loops is industry

best practice. The thimble prevents the load from coming into direct contact with the wires.

Wire rope clamps (DOG CLAMPS)

A wire rope clamp, also called a clip, is used to fix the loose end of the loop back to the wire rope. It

usually consists of a u-shaped bolt, a forged saddle and two nuts. The two layers of wire rope are

placed in the u-bolt. The saddle is then fitted over the ropes on to the bolt (the saddle includes two

holes to fit to the u-bolt). The nuts secure the arrangement in place.

Three or more clamps are usually used to terminate a wire rope.

Swaged terminations

Swaging is a method of wire rope termination that refers to the installation technique. The purpose of

swaging wire rope fittings is to connect two wire rope ends together, or to otherwise terminate one

end of wire rope to something else. A mechanical or hydraulic swager is used to compress and deform

the fitting, creating a permanent connection. There are many types of swaged fittings. Threaded

Studs, Ferrules, Sockets, and Sleeves a few examples.

Sockets

A socket termination is useful when the fitting needs to be replaced frequently. For example, if the

end of a wire rope is in a high-wear region, the rope may be periodically trimmed, requiring the

termination hardware to be removed and reapplied. An example of this is on the ends of the drag

ropes on a dragline. The end loop of the wire rope enters a tapered opening in the socket, wrapped

around a separate component called the wedge. The arrangement is knocked in place, and load

gradually eased onto the rope. As the load increases on the wire rope, the wedge become more

secure, gripping the rope tighter.

Eye splice

|

The ends of individual strands of this eye splice used aboard a cargo ship are seized with natural fiber

cord after the splicing is complete. This helps protect seaman's hands when handling.

An eye splice may be used to terminate the loose end of a wire rope when forming a loop. The strands

of the end of a wire rope are unwound a certain distance, and plaited back into the wire rope, forming

the loop, or an eye, called an eye splice.

|

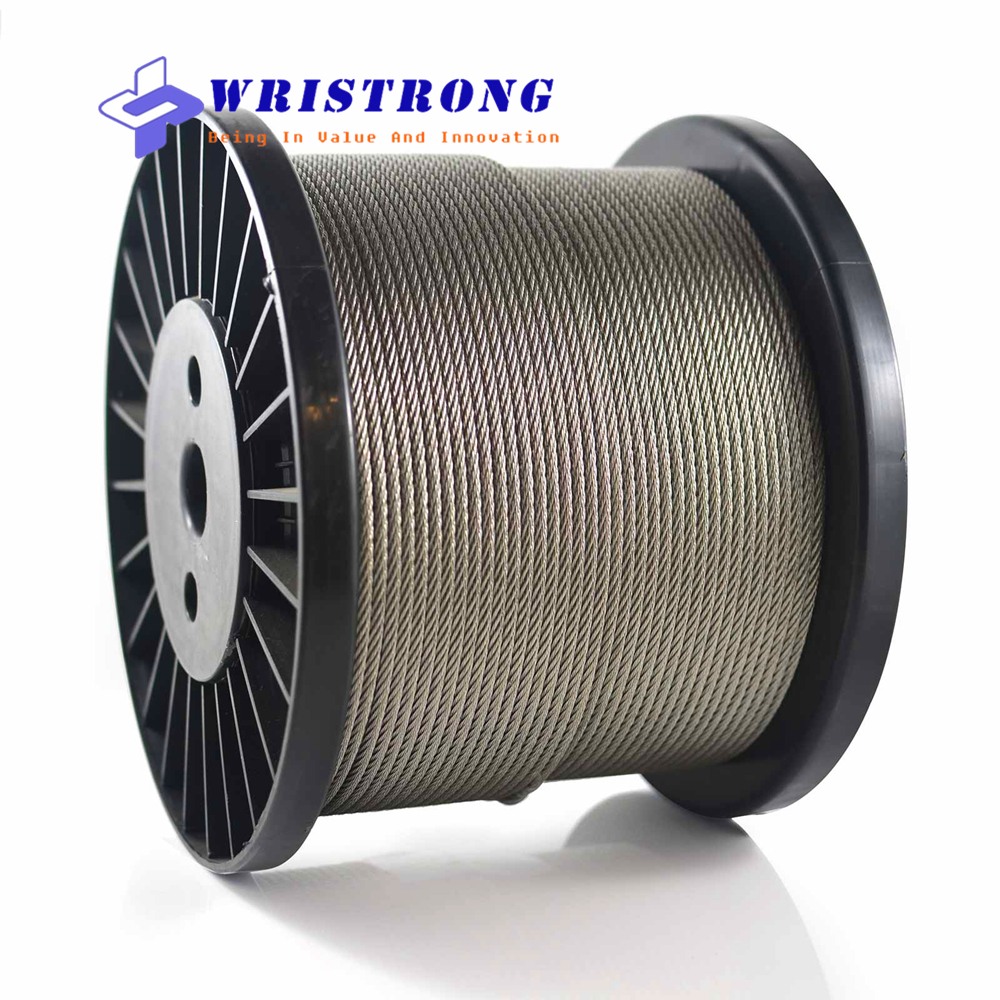

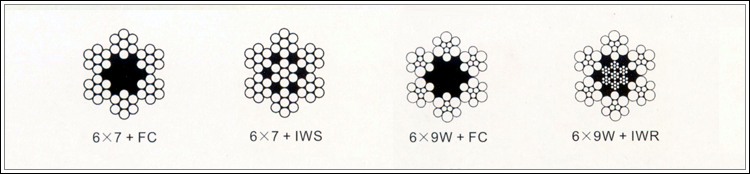

6*7、6*9W Steel Wire Rope (Ungalvanized)

|

|

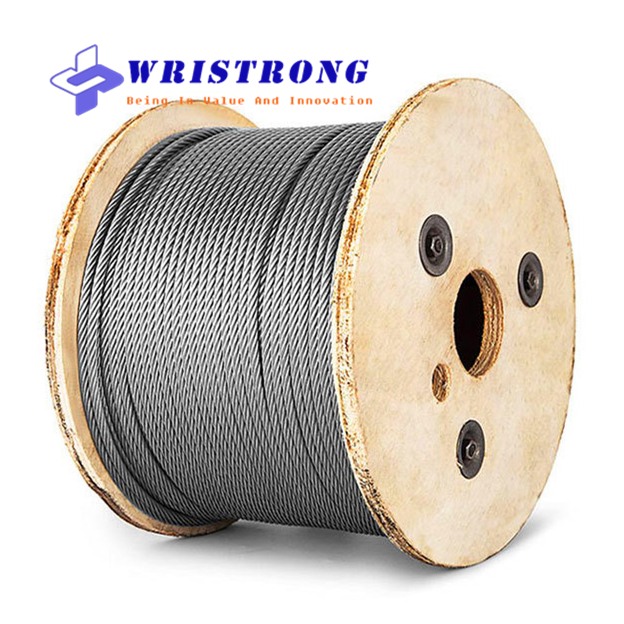

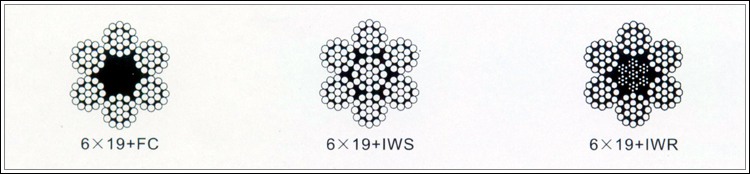

6*19 Steel Wire Rope (Ungalvanized and Galvanized)

|

|

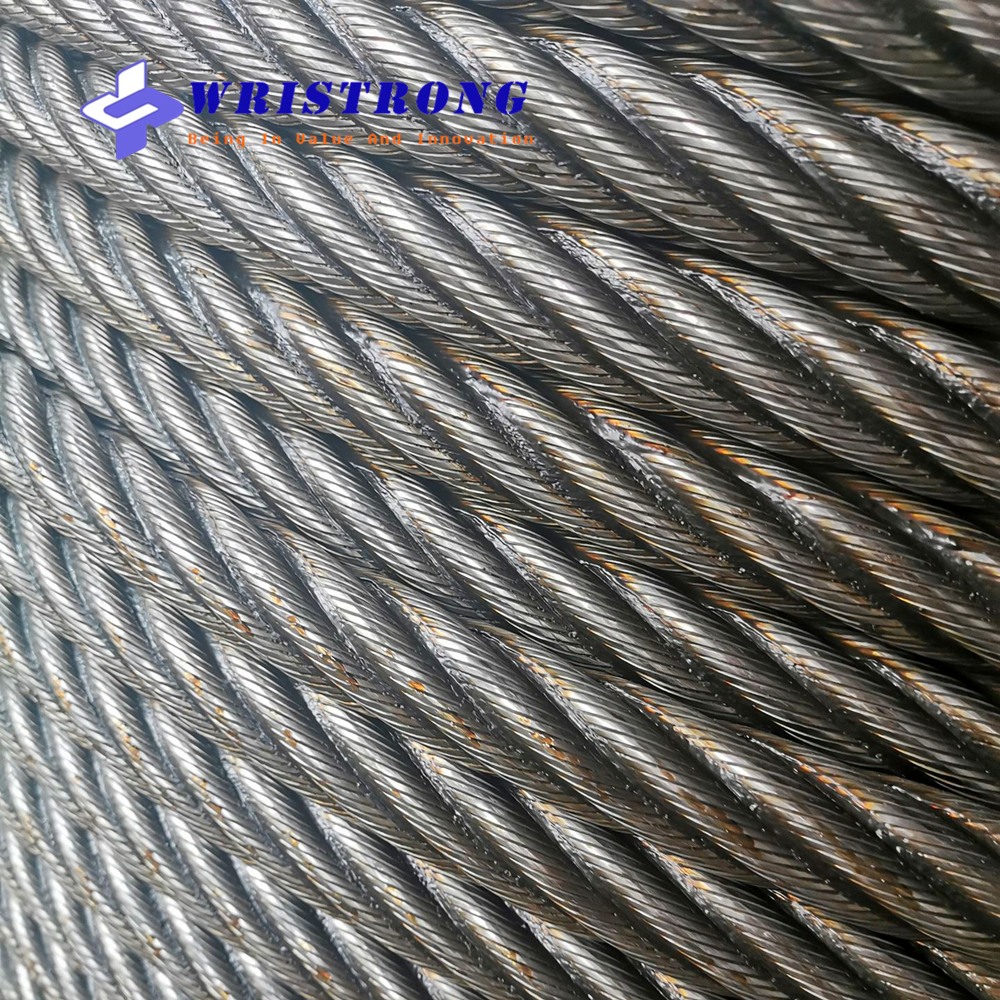

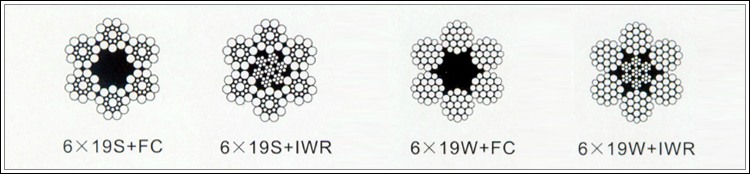

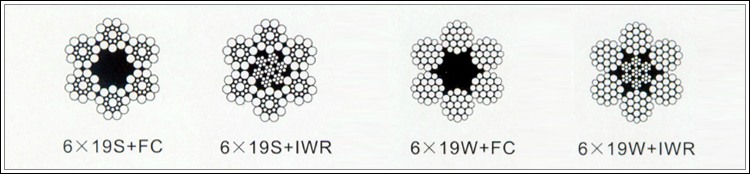

6*19S,6*19W Line Contacted Wire Rope (Ungalvanized and Galvanized)

|

|

|

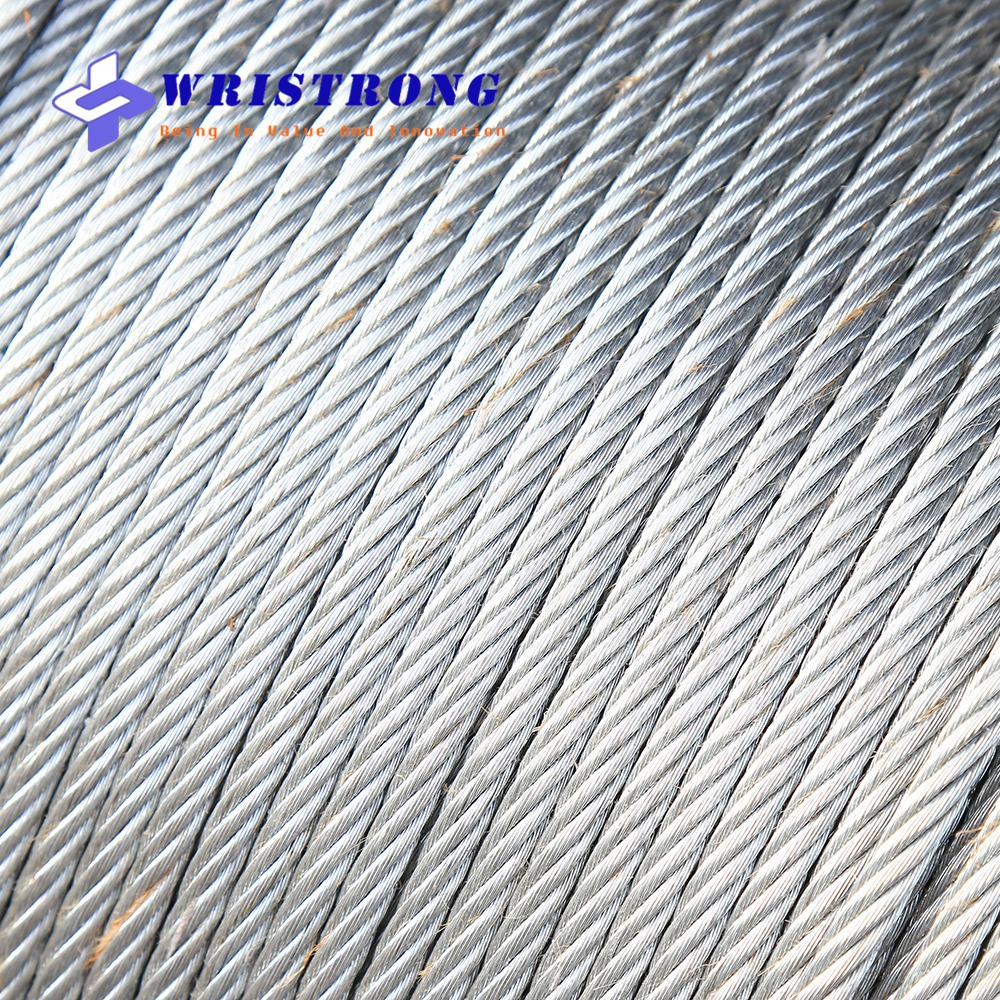

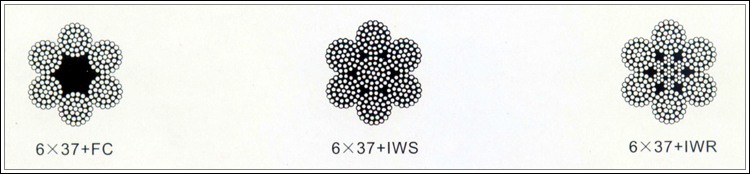

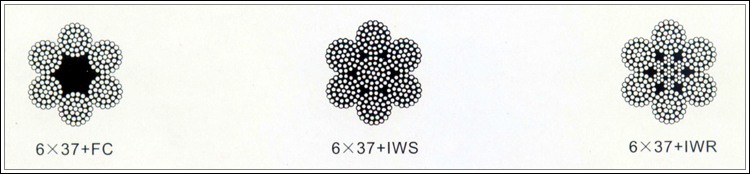

6*37 Steel Wire Rope (Ungalvanized and Galvanized)

|

|

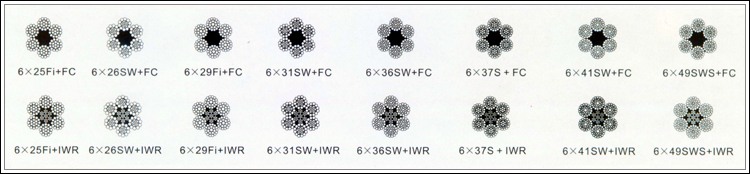

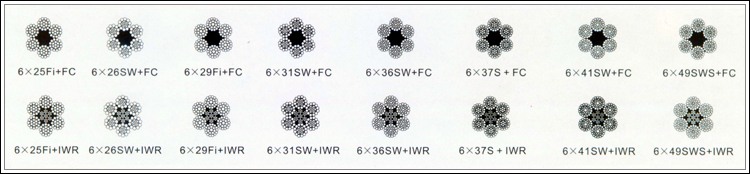

6*25Fi、6*29Fi、6*26SW、6*31SW、6*36SW、6*37S Line Contacted Wire Rope

( Ungalvanized and Galvanized)

|

|

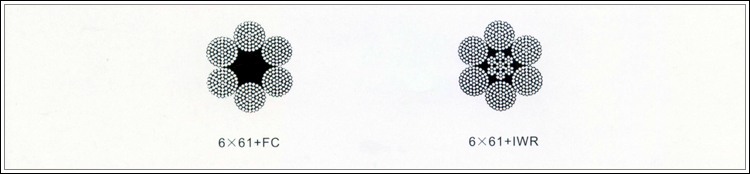

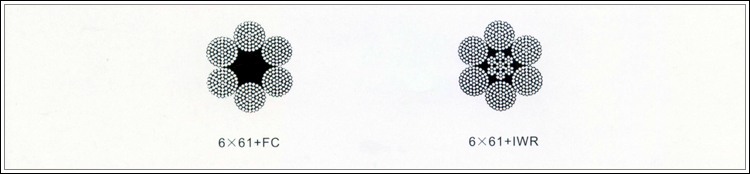

6*61 Steel Wire Rope (Ungalvanized and Galvanized)

|

|

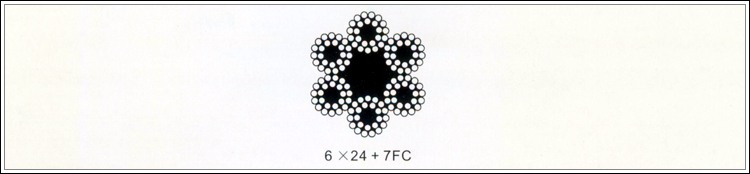

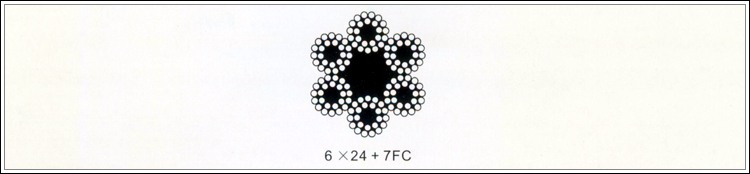

6*24 Steel Wire Rope ( Ungalvanized and Galvanized)

|

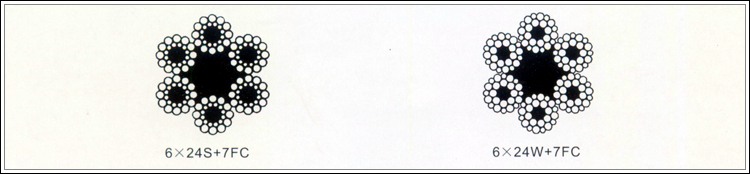

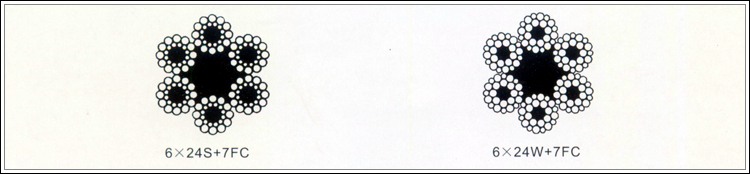

6*24S+7FC、6*24W+7FC Line contacted wire rope (Ungalvanized and galvanized) |

|

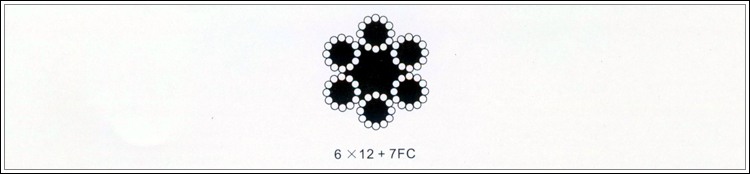

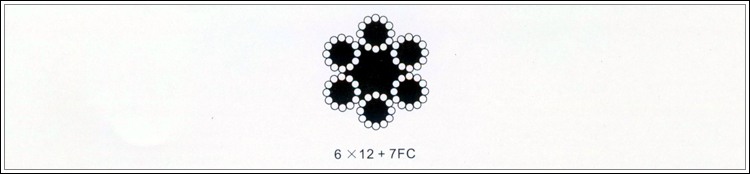

6*12 Steel Wire Rope (Ungalvanized and Galvanized)

|

|

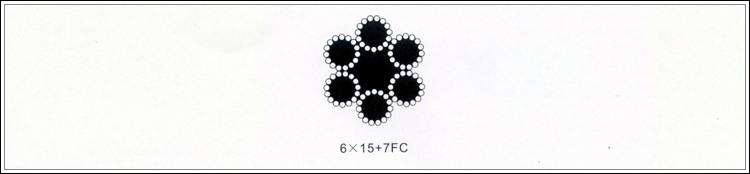

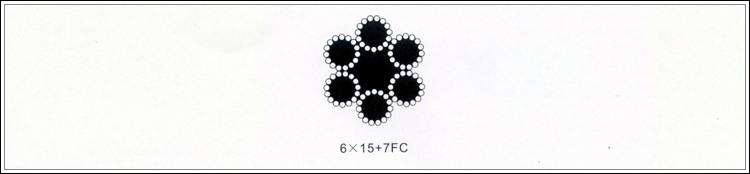

6*15 Steel Wire Rope(Ungalvanized and Galvanized)

|

|

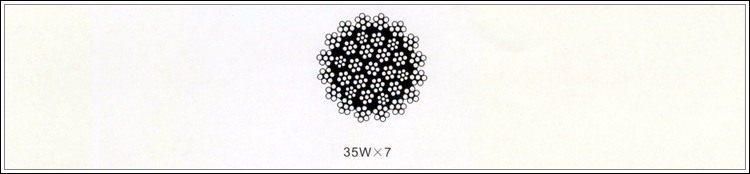

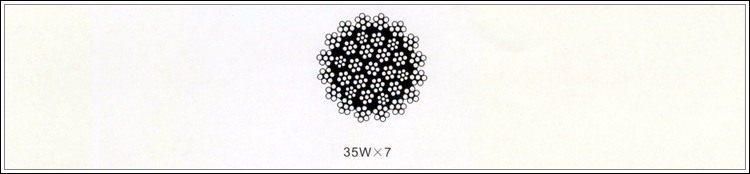

Non-rotating Steel Wire Rope With Many Layers (Ungalvanized and Galvanized)

|

|

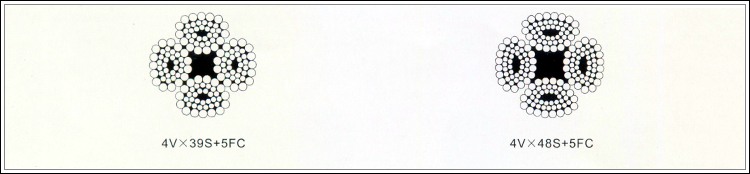

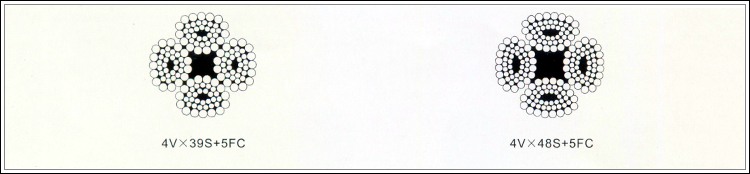

4 Strand flat Non-rotating Wire Rope(Ungalvanized and Galvanized)

|

|

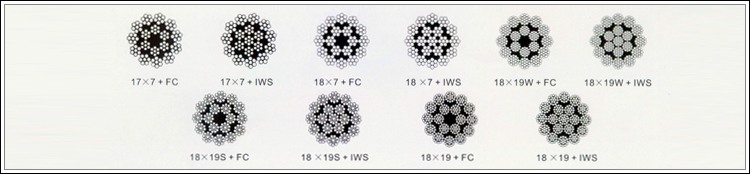

Non-rotating Steel Wire Rope With Many Layers (Ungalvanized and Galvanized)

|

|

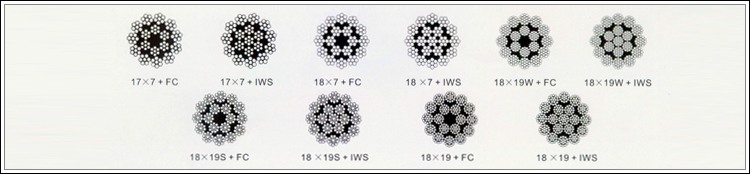

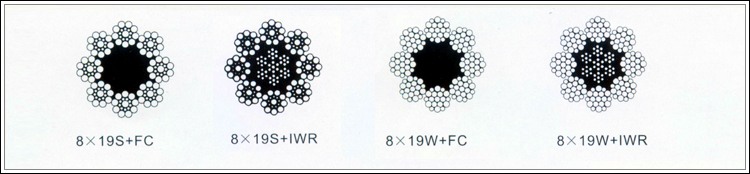

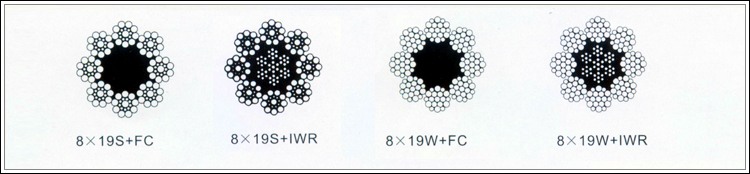

8*19S,8*19W Elevator Steel Wire Rope

|

|

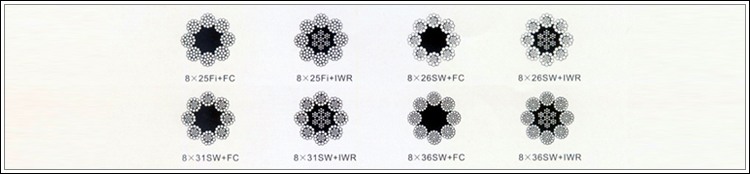

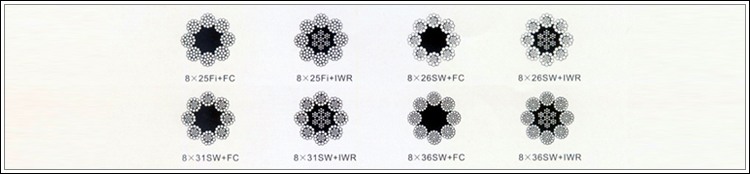

8*25Fi,6*26SW,8*31SW Line Contacted Wire Rope

|

|

Galvanized guy rope for Eletric Cable

|

|

Galvanized guy rope for the reinforcement of Optical Fibre Cable & Communication Cable

|

|

Galvanized steel wire rope for lock

|

|

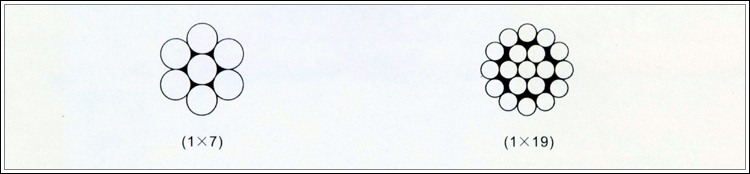

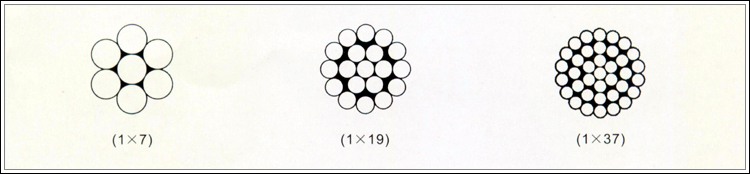

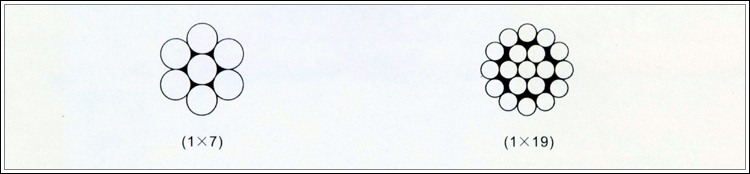

Steel wire ropes for aeronautical use

|

|

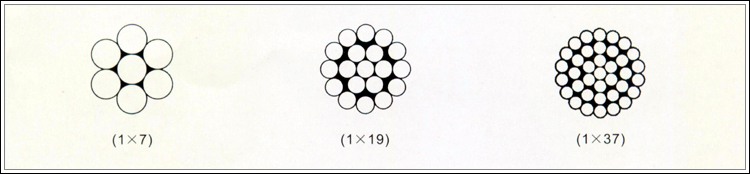

Steel wire ropes for aeronautical use

|

|

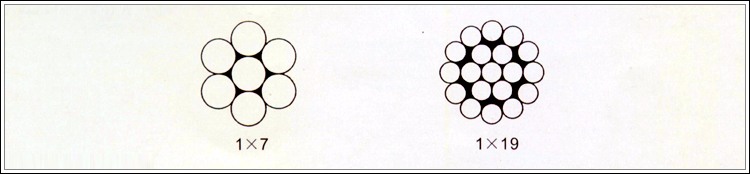

Steel wire ropes for aeronautical use-Steel wire Strand Rope

|

|