China Zhonglian Crane Lift Nuclear Power Station

Pubdate: Feb 17,2025 Preview: 2,706

China Zhonglian Crane Lift Nuclear Power Station

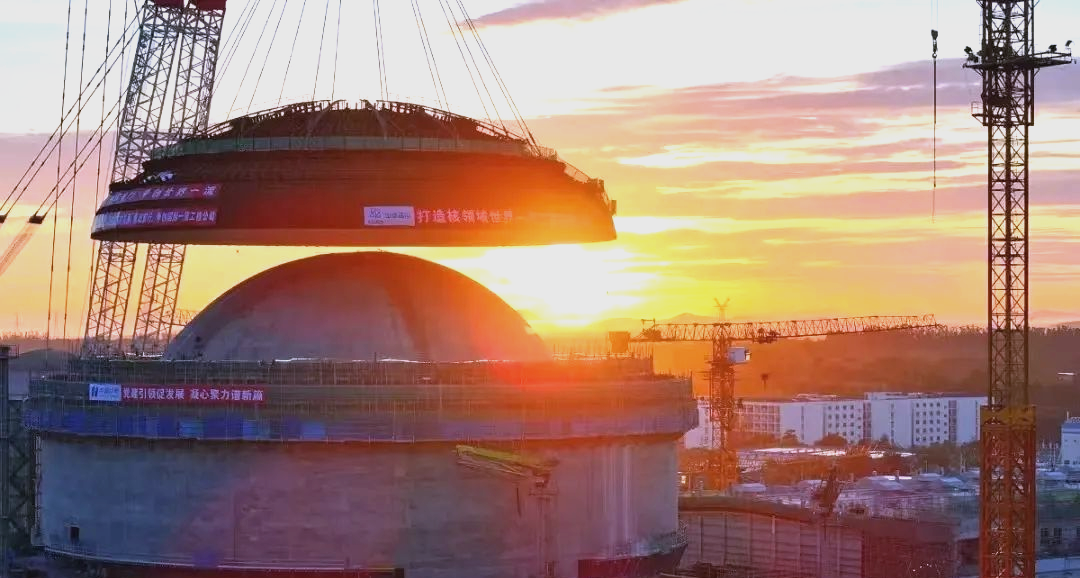

Zhonglian Heavy Industry Crane Aids in the Lifting of the Outer Dome of Changjiang Nuclear Power Unit 3, Demonstrating Outstanding Lifting Capabilities

Recently, Zhonglian Heavy Industry's crane has once again become the focus of attention, successfully assisting in the lifting of the outer dome of Unit 3 of the Changjiang Nuclear Power Station. This significant moment not only showcases Zhonglian Heavy Industry's professional capabilities in the field of nuclear power construction but also highlights its outstanding lifting capabilities.

During the critical moment of the outer dome lifting for Unit 3 of the Changjiang Nuclear Power Station, Zhonglian Heavy Industry's crane played a vital role once again. On October 18th, with the command "Prepare to lift" from the on-site lifting supervisor, a super-large outer dome module weighing approximately 600 tons was precisely and safely placed on top of the nuclear island by a 3,200-ton crawler crane. This successful lifting not only added a majestic silhouette to the nuclear power unit but also marked the near completion of the nuclear island's main structure construction, paving the way for subsequent installation, commissioning, and grid connection.

The lifting of the outer dome module is a landmark moment in the construction of the Changjiang Nuclear Power Station. Located at the top of the nuclear island reactor building, the module is an irregularly shaped hemispherical head with a base diameter of about 52 meters and a height of 12 meters. It primarily serves as a formwork for the concrete pouring of the nuclear island's outer dome, providing necessary support for the subsequent pouring of the nuclear island's outer dome. The nuclear island shell plays a crucial role in nuclear power engineering, as it not only provides protection but is also an integral part of the nuclear island's safety protection system.

The outer dome module lifted this time weighs an astonishing 600 tons. Due to the large size, heavy weight, and thin-walled characteristics of the outer dome structure, it is highly susceptible to deformation during the lifting process, posing significant challenges for precise positioning. However, Zhonglian Heavy Industry's 3,200-ton crawler crane, with its millimeter-level lifting precision and stable, efficient lifting actions, successfully placed the outer dome of Unit 3 of Changjiang Nuclear Power Phase II in the designated position.

Unit 3 of Changjiang Nuclear Power Station, as the first "Hualong One" nuclear power unit launched during China's 14th Five-Year Plan period, has attracted widespread attention throughout its construction. During this process, Zhonglian Heavy Industry's crane has always shouldered important responsibilities, successfully completing key tasks such as the lifting of the ring beam and rail, the main beam of the crane, and the inner dome. These outstanding performances have provided strong equipment support for the smooth progress of the Changjiang Nuclear Power project.

How does the 3200-ton crawler crane ensure such precision during the lifting process?

The 3200-ton crawler crane ensures such precision during the lifting process through a combination of advanced technologies and engineering features:

-

High-Precision Slewing Mechanism: The crane is equipped with a high-precision slewing mechanism that uses an imported six-row roller external gear slewing bearing. This design provides strong load-bearing capacity and high precision, ensuring stable and accurate movements.

-

Advanced Control Systems: Modern crawler cranes, like the 3200-ton model, often integrate advanced control systems that allow for fine-tuned movements and precise positioning of heavy loads. These systems can include programmable smart buttons, vibration handles, and other ergonomic controls that enhance operator precision.

-

Load Moment Indicator (LMI): The crane features an independent computerized safety control system known as the Load Moment Indicator. This system automatically detects the load and boom angle, providing real-time data to the operator to prevent overloading and ensure safe and precise lifting.

-

Telematics and Real-Time Monitoring: The crane is equipped with telematics systems that provide real-time updates on machine condition and maintenance needs. These systems also allow for remote monitoring and adjustments, ensuring optimal performance and precision.

-

Advanced Safety Features: The crane includes multiple safety features such as anti-two-block systems, boom limit devices, and emergency stop mechanisms. These features not only enhance safety but also contribute to precise control during lifting operations.

-

Remote Control Systems: Some crawler cranes are equipped with remote control systems that allow operators to control the crane from a safe distance. This technology enhances precision by providing fine-tuned movements and accurate positioning.

-

Lattice Boom Design: The lattice boom design offers a high strength-to-weight ratio, enabling the crane to lift heavy loads with stability and precision. This design also allows for better load distribution and reduced ground pressure.

These features collectively enable the 3200-ton crawler crane to achieve millimeter-level precision during lifting operations, making it ideal for complex and demanding tasks such as the outer dome lifting in nuclear power plant construction.