Eye & Eye Web Slings For Lifing 4 Inch Wide

Please Note:

If you have any special requirements, you can contact us bellow and we will reply you as soon as possible.

Request A QuoteProduct Specification:

Eye & Eye Web Slings For Lifing 4 Inch Wide | Hot Sales

Wristrong manufactured 4 " wide web sling with reinforced(protective sleeves stitched onto eyes or a lining cloth stitched inside of the eyes) reverse eyes is called type 4 web sling-(Web sling made with both loop eyes formed as in Type III, except that the loop eyes are turned at a right angle to the plane of the sling body. This type of sling is commonly referred to as a twisted eye sling.) and is made of double ply Class 7 (see the web sling specification bellow to know what is class 7 ) 4" wide lifting belts, working load limit is 11,000lbs. Other brief details go as follows:

Material: High tensile strength polyester yarn

Vertical W.L.L: 11,000LBS

Basket W.L.L: 22,000LBS

Choker W.L.L: 8,800LBS

Safety Factor: 5:1

Width: 3"

Length: As requested

*Proof Test Certificate: A proof test can be carried out and provided with a certificate upon request.

Color: White,Yellow,Green,Black,Pink,Red,etc

Standard: ASME/ANSI B30.9,WSTDA-WS-1

Characteristic: 100% acc to the standard, wearable & durable

Package: Carton boxes+pallets

Currently China Wristrong is able to manufacture web sling with loading capacity (W.L.L) upto 120,000LBS, accaroding to American synthetic web sling standards ASME/ANSI B30.9,WSTDA-WS-1.*Proof Test:

Generally a web slings are not required to be proof tested prior to their initial use if all components are new. However, some lifting sites might request a proof test for more safety consideration. Wristrong provides additonal proof test upon request by charging some qualified tester fees.

Proof Testing Procedures - When web slings are proof tested, the testing should be conducted using a pin diameter sized in accordance with Table 3-1 and shall be tested in accordance with the following:

A. For single-leg or multiple leg slings and endless slings, legs shall be proof loaded to a minimum of 2 times the single-leg vertical hitch rated load.

B. The proof load for fittings attached to single legs shall be a minimum of 2 times the single-leg vertical hitch rated load.

C. Master links for two-leg bridle slings shall be proof loaded to a minimum of 4 times the single-leg vertical hitch rated load.

D. Master links for three-leg bridle slings shall be proof loaded to a minimum of 6 times the single-leg vertical hitch rated load.

E. Master links for four-leg bridle slings shall be proof loaded to a minimum of 8 times the single-leg vertical hitch rated load.

USA Standard Web Sling Specifications:

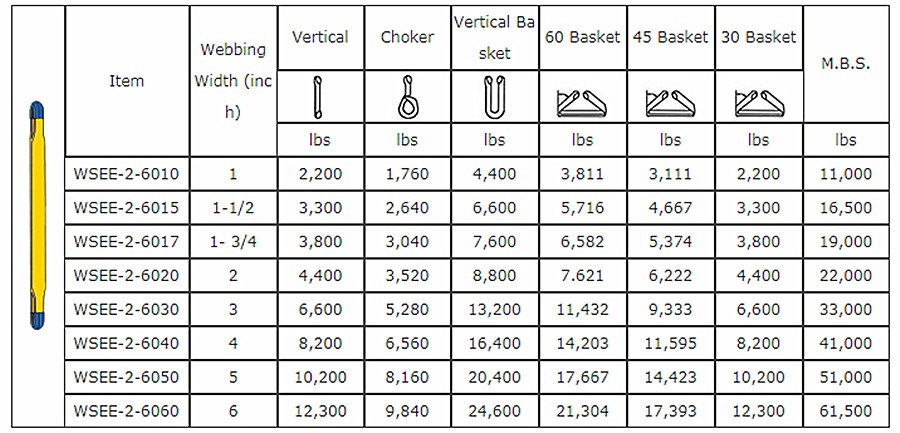

Double Ply Eye & Eye Webbing Sling Class 5

Class 5 means rated loads are based on a stuffer weave construction webbing possessing a minimum certified

tensile strength of 6,800 lbs/inch width.

Class 5 means rated loads are based on a stuffer weave construction webbing possessing a minimum certified

tensile strength of 6,800 lbs/inch width.

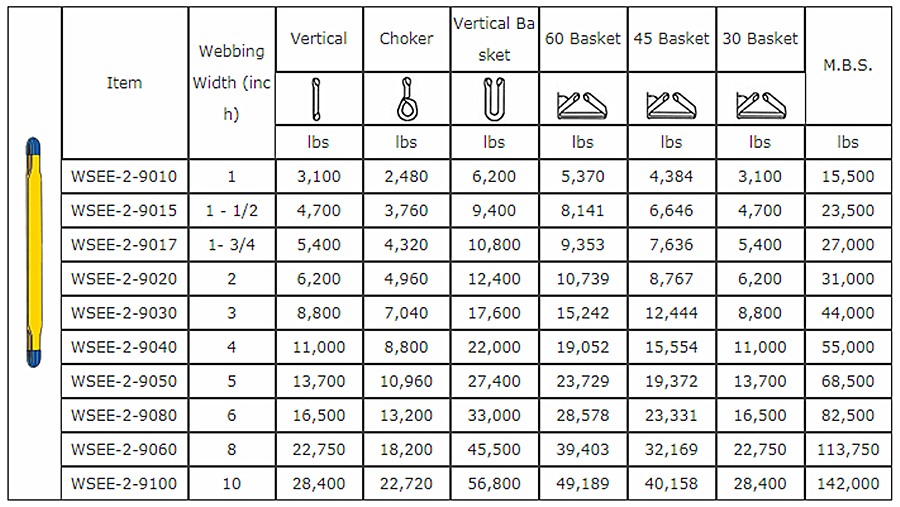

Double Ply Eye & Eye Webbing Sling Class 7

Class 7 means rated loads are based on a stuffer weave construction webbing possessing a minimum certified tensile strength of 9,800 lbs/inch width.

Class 7 means rated loads are based on a stuffer weave construction webbing possessing a minimum certified tensile strength of 9,800 lbs/inch width.

How to Order lifting web slings?

Generally Our professional sales team will advise you on how to order the webbing slings according to your lifting conditions and environment. However, some times you may know well about what kind of web slings you need or you may just buy same web slings that you are using now. In this case you can just let us know following information:

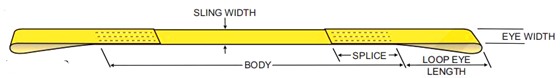

1: The most import 1: size information showed in the web sling diagram above.

2: The most imporat 2: Working load limit (Load capacity).

3: Safety factor: Usually American standard web slings come with a safety factor of 5:1. But If you have other application of the sling, like single use / trip / one way lifting use, it is also fine to go with 4:1, or 3:1, which will save the cost by a lot. If you don't know what is single use slings, you can find out the link Wristrong One Way Slings.

4: Color of the web sling. We can manufacture nearly all the normal colors according to your color code.

5: Packaging: Our normal packing way is carton box + Pallet, which is proven to be a very safe way during transportation. However, if ou have any special requirement on packages, just let us know.

6: Order Quantity and trade incoterm.( FOB, CIF or DAP,etc)

7: Delivery time: 25-30days for any made to order. For some big orders, please let us know your usage plan and we will try our best to keep up with your pace.

8: Payment term: Regular payment via T/T, 30% down payment, 70% balance before shipment. But if you have other idea on the payment ways, you can negotiate with us.

If you would like to get more information or place order direcetly, you can just contact us right away.WEB SLING INSPECTION: A three stage procedure is recommended to help ensure that slings are inspected with appropriate frequency.

Initial Inspection - Prior to use, all new, altered, modified or repaired web slings shall be inspected by a designated person to verify compliance with the applicable provisions of this Chapter.

Frequent Inspection - In normal service conditions, a visual inspection for damage shall be performed by the user or other designated person each day or shift before the sling is used. In severe service conditions, a visual inspection for damage shall be performed by the user or other designated person before each use. Manufacturer’s recommendations must be followed if a higher rate of inspection frequency, such as before each use, is prescribed. Written records are not required for frequent inspection.

Periodic Inspection - A complete inspection for damage shall be performed by a designated person. This inspection should be done by someone other than the individual(s) who most commonly perform the frequent inspection.

A. Periodic inspection intervals shall not Periodic Inspection Frequency - exceed one year. The frequency of periodic inspections should be based on:1. Frequency of sling use.

2. Severity of service conditions.

3. Nature of lifts being made.

4. Experience gained on service life of slings used in similar circumstances.

B. The guidelines for time intervals are as follows: Time Interval Guidelines -1. Normal Service - Yearly

2. Severe Service - Monthly to quarterly

3. Special Service - As recommended by a qualified person

C. A written record that the most recent inspection was Written Records - performed shall be maintained documenting that the event occurred. It is not required that the condition of individual slings be recorded during the periodic inspection. If documentation of the individual slings is maintained, it should be based upon a unique sling serial number, color coding, electronic tracking (RFID) or other means. See Appendix “Web Sling Inspection Form”. If individual tracking is not maintained, the inspection process should provide some means of identifying which slings have been inspected at the periodic level of inspection.