Grade 70 Transport Chains(AS/NZS 4344:2001)

Please Note:

If you have any special requirements, you can contact us bellow and we will reply you as soon as possible.

Request A QuoteProduct Specification:

Grade 70 Transport Chains(AS/NZS 4344:2001) From China Wristrong

Wristrong Industry provides virous types of alloy steel chains. All of our chains are manufactured from hardened and tempered alloy steels and has a high resistance to impact and wear to meet critical requirements of EN818-2,AS4344,AS2321,DIN5685A/C,NACM,OSHA,ASTM80,NACM84/90, NACM96,DIN764,DIN763,DIN766,ETC.

Wristrong Grade 70 Transport chains(AS4344) are designed and manufactured for the local transport industry and compliant with the requirements of Australian and New Zealand AS/NZS 4344:2001. Our grade 70 transport chains for Australian and New zealand market are embossed with the digits 4344 followed by the first two digits of the chain’s lashing capacity and will be quenched and tempered, proof tested before exportaion. The normal finish for the grade 70 transport chains from us is yellow chromated or zinc plated , but please just let us know if you have any unique requirements, we will do my best to meet your needs.

In addition, we can also provide the chains at any lengths with end fittings like clevis grab hooks,lug links,slip hooks and load chain kits.The features of our Grade 70 Transport Chains go as follows:

-Manufactured to AS/NZS 4344:2001

-Manufacturer’s test certificate can be supplied as required.

-Grade Number & Lashing Capacity marked each meter if required.

-Safety Factor: 4:1

-Quenched and tempered, proof tested applied in each order.

-Yellow chromated or zinc galvanized outside treated.

-Free Sample available upon request.

-Competitive prices.

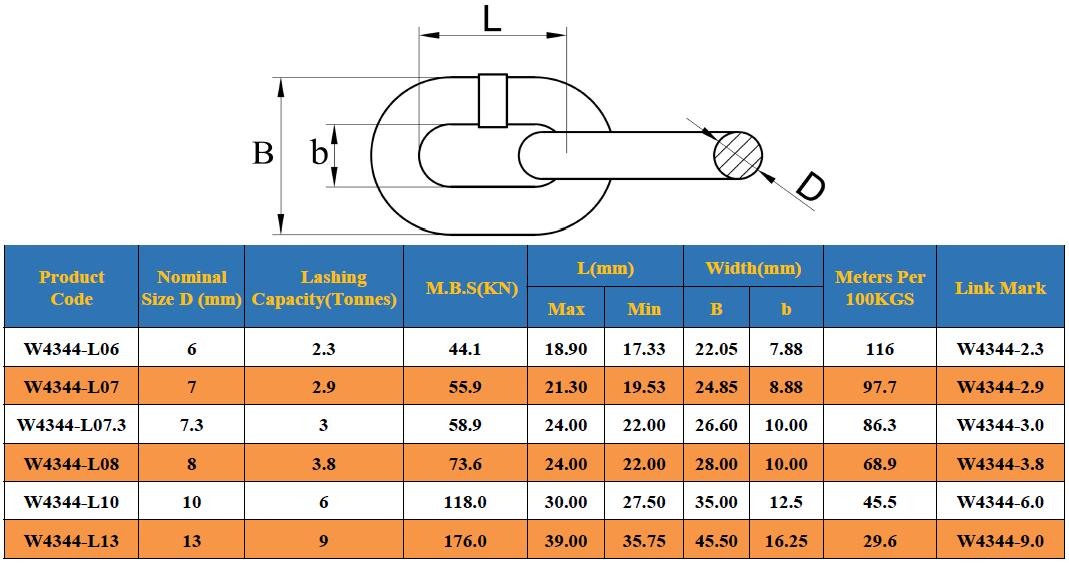

WARNING: DO NOT EXCEED THE WORKING LOAD LIMITS ! NOT FOR OVERHEAD LIFTING !Specification On Grade 70 Transport Chains(AS/NZS 4344:2001):

The Production Process of Wristrong Welded Link Chains:

1:FORMING: Link shape and V notche check required during the full procedure. Dimensions check required.

2:WELDING: The weld was produced using the resistance butt processes and positioned in the centre of one leg of the link. It was smoothly finished all round. The links and welds shall not show fissures, notches or similar faults that are detrimental to the chain after welded. The diamater of the material at the weld was nowhere exceed the dimenstions requirements and not.less than the diameter of the material of the link.For smooth welded chain, fins caused by welding will be removed and the weld will be smoothly finished all round. The positioning of the weld at the centre of the straight barrel and the tolerances imposed on protrusions at the weld will provide the required clearances.

3:CALIRATING: Dimension check required for each calibration. Proof load on calibration shall be record for each batch.

4:MARKING: Chain Calibration Machine. Tow series available for 5mm to 16mm chain diameter marking/stamping. One key start. Adopt PCC control system with automatic-stop function when encounter fault, Reasonable mould design. Add self-weight function for the machine to increase the operational stability.

Pneumatic marking system which can also mark on two links at the same time.5:HEAT TREATMENT: All the chain has been intermediate-frequency heat treated, it was hardened from a temperature above the AC3 point and tempered before being subjected to the manufacturing proof force. The termpering conditions was at least as effective as a temperature of 400°C maintained for a period of 1 hour. When proposed for verification, sample chains has be tested after they have been reheated to and maintained for 1 hour at 400°C and then cooled to room temperature.( AS 2321:2014 required the chain to be tempered in temperature at least 200°C for V200 and 380°C for V400).

Hardness check required.

Proof load and breaking load tests required.

Elongation measurement required.

Bend test required.