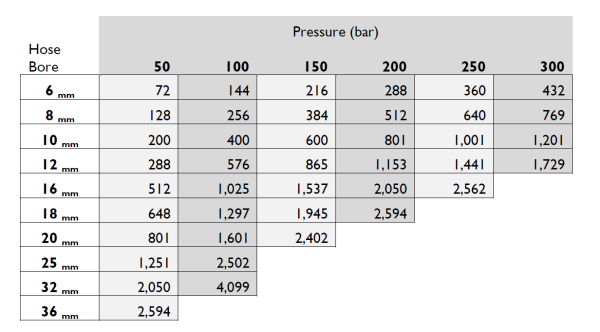

Where:

Thrust Force: The force generated from pressurised fluid or gas ejecting from a damaged

hose, in Newtons.

Hose Pressure: The internal gauge pressure of the specified hose, in bar.

Hose Cross Sectional Area The cross-sectional area of the nominal bore of the specified

hose, in mm2. Calculated by using: 𝜋 × r2 (see note*)

Whip Check SWL: The minimum Safe Working Load (SWL) that is required for the whip

check for a specified hose, in kg.

Gravitational Acceleration: 9.81 m/s2.

Whip Check MBL: The Minimum Breaking Load (MBL) that is required for the whip check

for a specified hose, in kg.

Factor of Safety: A Safety Factor of 5 should be used, aligned with rigging and lifting

protocol. This safety factor also covers any increased test pressure requirements of hoses

needing to be restrained whilst under test.

Notes.

* The number 𝜋(pi) is a mathematical constant. It is defined as the ratio of a circles

circumference to its diameter. It is calculated as 3.142 (to three decimal places)

An example calculation is shown below to determine the minimum breaking load (MBL)

required for a whip check fitted to a 6.35 mm hose.

Metric Units Example Calculation. For a 6.35 mm nominal bore certified gas hose

pressurised to 200 bar:

Thrust Force = Hose Pressure × Hose Cross Sectional Area

Hose Cross Sectional Area = (𝜋 x r2) = 31.67 mm2

Thrust Force = 200 bar × 31.67 mm2 x 0.1= 633.4 N

Whip Check SWL = Thrust Force / 9.81 = 633.4 / 9.81 = 64.57 kg

Whip Check MBL = SWL × Factor of Safety = 64.57 × 5 = 322.83 kg

Therefore, the whip check required to restrain the hose in this example must have a

minimum SWL of 65 kg, or an MBL of 323 kg.

All restraint accessories (hooks, shackles, carabiners) must also meet this SWL/MBL.

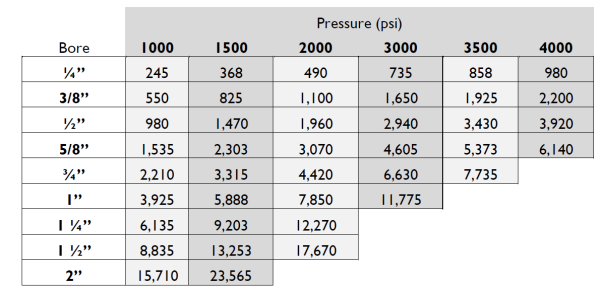

Imperial Units.

MBL is calculated by using the three-step equation below.

Thrust Force = Hose Pressure x Hose Cross Sectional Area

Whip Check SWL = Thrust Force (see *Note on units below)

Whip Check MBL = Whip Check SWL x Safety Factor

Where:

Thrust Force: The force generated from high pressure fluid or gas ejecting from a damaged

hose, in lbf.

Hose Pressure: The internal gauge pressure of the specified hose, in psi.

Hose Cross Sectional Area The cross-sectional area of the nominal bore of the specified

hose, in in2. Calculated by using: 𝜋 × r2 (see note**)

Whip Check SWL: The minimum Safe Working Load (SWL) that is required for the whip

check for a specified hose, in lb.

Whip Check MBL: The Minimum Breaking Load (MBL) that is required for the whip check

for a specified hose, in lb.

Factor of Safety: A Safety Factor of 5 should be used, aligned with rigging and lifting

protocol. This safety factor also covers any increased test pressure requirements of hoses

which will also need to be restrained whilst under test.

Notes on units –

*The imperial unit of Thrust Force should be defined in Slugs. The slug is a unit of mass

associated with British Imperial or United States customary units. It is a mass that

accelerates by 1 ft/s2 when a force of one pound is exerted on it. (1 Slug has a mass of

32.174 lb). Therefore, in the second equation, the operation to convert the force into slugs cancels out the gravitational acceleration of 32.174 ft/s2, meaning the SWL equals the Thrust Force.

** The number 𝜋(pi) is a mathematical constant. It is defined as the ratio of a circles

circumference to its diameter. It is approximately calculated as 22/7 (or 3.142 to three

decimal places)

An example calculation using imperial units is shown below to determine the MBL required

for a hip check fitted to a hose.

Imperial Units Example Calculation. For a 1/4 nominal bore certified gas hose

pressurised to 2900 psi:

Thrust Force = Hose Pressure × Hose Cross Sectional Area

Hose Cross Sectional Area = (𝜋 x r2) = 0.049 in2

Thrust Force = 2900 psi × 0.049 in2 = 142.1 lbf

Whip Check SWL = Thrust Force = 142.1 lb

Whip Check MBL = Whip Check SWL × Factor of Safety = 142.1lbf × 5 = 710.5 lb

Therefore, the whip check required to restrain the hose in this example must have a

minimum SWL of 143 lb, or an MBL of 711 lb. PS: The safety factor in United States is 5:1, it will be 7:1 in Europe for the round slings. The flat webbing slings also could be used as hose restraint sling, the safety factors are same as that in United States and Europe, but be cautious that it will require 8:1 safety factor in Australia and New Zealand.

All restraint accessories (hooks, shackles, carabiners) must also meet this SWL/MBL. All the types of the Round Slings above mentioned, contact our Sale Team if you are interested in.