Pictures Illustrated: Suggested Tips for Using Synthetic lifting slings Safely

Pubdate: Mar 8,2025 Preview: 3,038

Pictures Illustrated: Suggested Tips for Using Synthetic lifting slings Safely

With the development of the industry, hoisting operations are being applied more and more widely, and safety accidents in hoisting operations have received increasing attention. Using synthetic lifting slings correctly can reduce accidents, improve the safety factor, and enhance work efficiency.

How to use lifting slings correctly? WRISTRONG suggests starting from the following aspects:

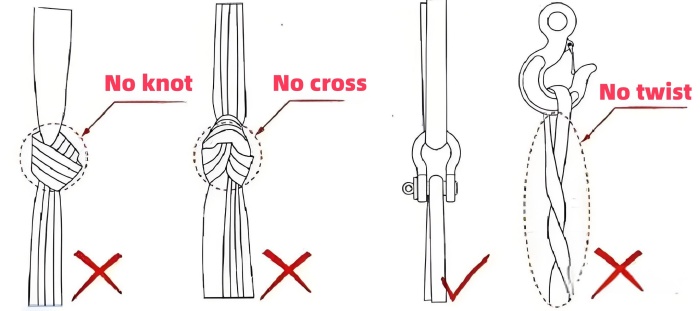

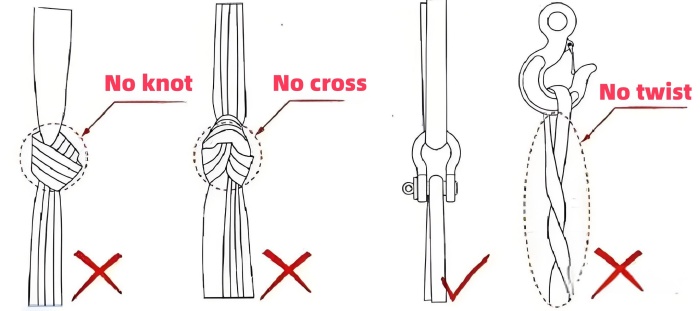

3. In hoisting operations, lifting slings are not allowed to cross or twist, and it is not allowed to tie knots or twists. Special lifting sling connectors should be used for connection.

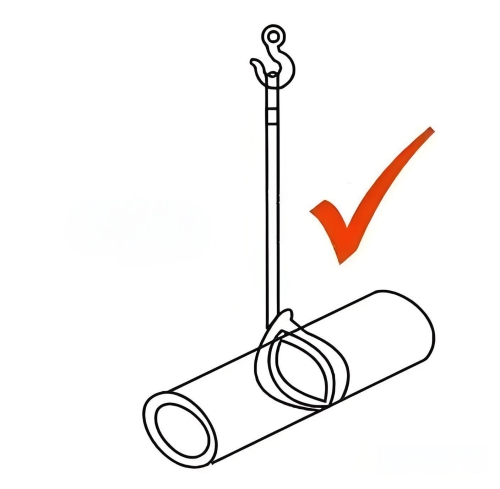

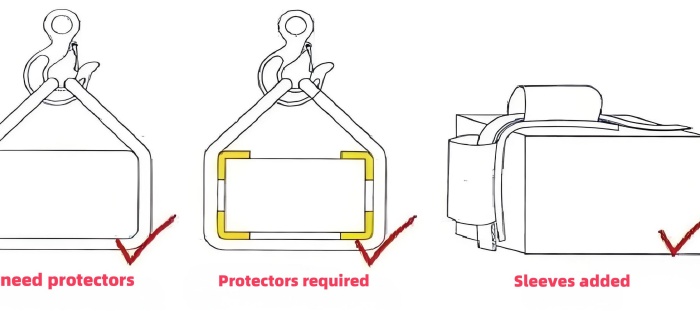

4. When hoisting goods with sharp corners or edges, methods such as using protective sleeves and corner protectors must be adopted to protect the lifting slings, so as to extend the service life of the lifting slings. It is strictly prohibited to use lifting slings on rough surfaces to prevent the lifting slings from being cut by the sharp corners or scratched by the rough surface.

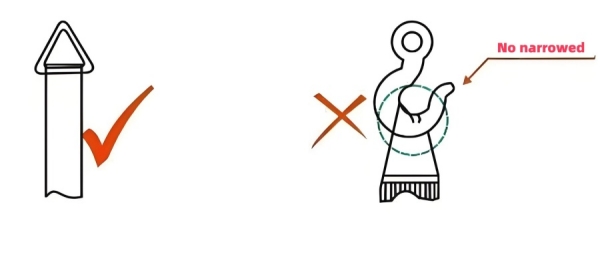

5. When using a flat lifting sling, due to the curved part of the hook, the flat lifting sling cannot bear the load evenly in the width direction, which is affected by the inner diameter of the hook. When the diameter of the hook is too small, it is not fully combined with the eyelet of the webbing. The correct connector should be used for connection.