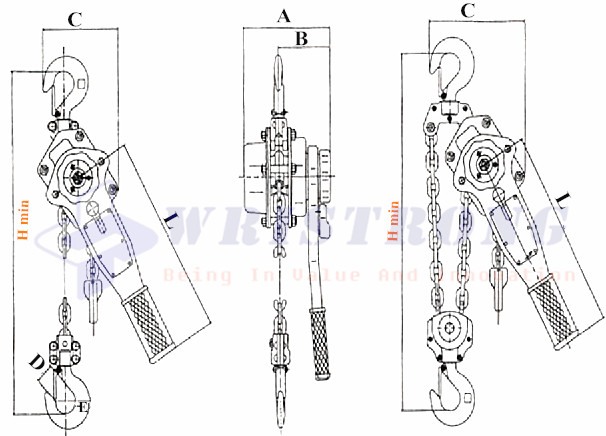

Ratchet Lever Hoists-Lever Blocks-HSHE Series

Please Note:

If you have any special requirements, you can contact us bellow and we will reply you as soon as possible.

Request A QuoteProduct Specification:

Ratchet Lever Hoists-HSHE Series | Lever Blocks | China Wirstrong® Manufacturing

A lever hoist is a manual device used to lift, lower, or pull a load and to apply or release tension. It utilizes a ratchet and pawl mechanical configuration to incrementally raise or lower a load or to apply or release tension.

Lever hoists and pullers have the advantage of being easy to transport, require minimum set-up, and are a practical option in confined spaces. They are suitable for different applications ranging from heavy-duty construction work to day-to-day maintenance and repair jobs.

Feathures Of Lever Blocks-Ratchet Lever Hoists-HSHE Series:

-Driving shaft with three-point support special design, better transmission balance capacity, higher anti impact load capacity..

-High-strength soft hook with safety bayonet latch clamp.

-Aluminum hand wheel, comfortable, light weight.

-The lever with ribs along edge provide high strength and high ability to fight against deformation.

-Reasonable lever connected with the body structure, flexible load.

-Open chain guide mechanism, the operating environment adaptability.

-Sealed bearings to increase the efficiency of maintenance.

-Design with ratchet bushings, improve braking reliability.

-Complies with EC Council Directive 2006/42/EC Machinery, ASME B30.16, AS 1418.2

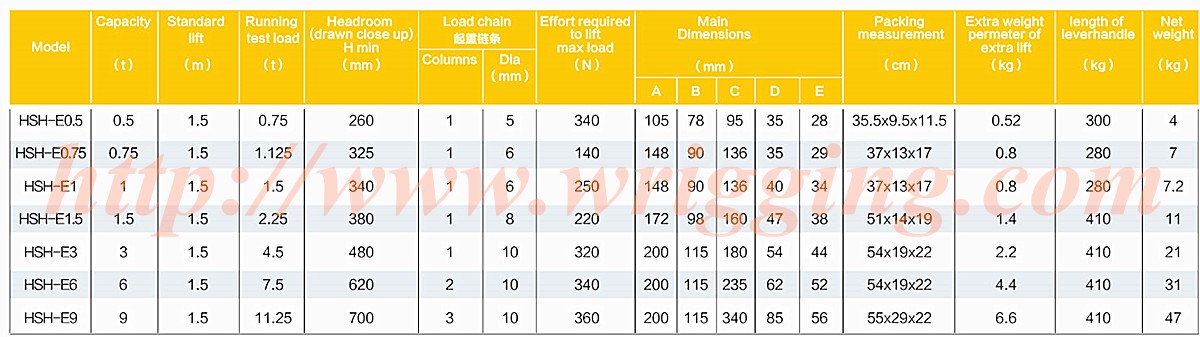

-Overload protection device.Specification and different capacities on HSHE Series Ratchet Lever Hoists:

Ensure that the chain block name plate and WLL is clearly visible and legible. The pre-use inspection for a chain block should include the followings:

Load chain

Inspect chain for wear.

Inspect chain for gouges, nicks, arc burns, twisted & bent links and corrosion.

Inspect for correct reeving on multi-reeved units (3 and 5 tonne)

Lift wheels & Sheave wheels

Inspect lift wheel for foreign material, wear and corrosion.

Inspect dead end pins for wear, tightness and corrosion.

Hooks

Inspect hooks for signs of opening, cracking, bending, arc burns and corrosion.

Hooks should swivel freely.

Inspect safety latches for condition & operation.

Measure the hook throats for allowable service openings.

Hand chain

Inspect chain for wear.

Inspect chain for twisted or gouged links and corrosion.

Inspect connecting link for signs of opening.

Miscellaneous

Inspect frame and covers for distortion, cracks, gouges, corrosion & other damage.

Inspect hangers (3 and 5 tonne) for cracks, gouges, corrosion & other damage.

Inspect unit for clear WLL identity.