Single Use-One Trip Lifting Web Slings: Efficient “Movers” in the Steel Industry

Pubdate: Mar 13,2025 Preview: 2,818

Disposable Web Slings: Efficient "Movers" In The Steel Industry

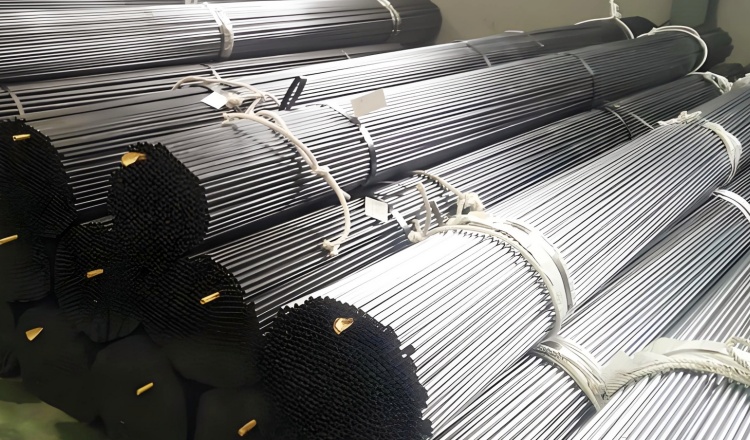

In the huge and complex production system of the steel industry, the handling and transportation of materials are crucial links. Single Use-one trip lifting web slings, as a seemingly simple but extremely useful tool, are gradually becoming a powerful assistant for steel enterprises to improve production efficiency and ensure safe production. A thorough understanding of the application of Single Use-one trip lifting web slings in the steel industry is of great significance for optimizing the steel production process.

Single Use-one trip lifting web slings, also called disposable lifting slings, play an irreplaceable and important role in the steel industry. From a cost perspective, they have remarkable economic benefits. Compared with traditional metal containers or reusable packaging, Single Use-one trip lifting web slings are inexpensive and can effectively reduce packaging and transportation costs. For the steel industry, which has a large throughput of materials, the cost reduction accumulated over a long period is quite substantial.

In terms of operational convenience, their advantages are also extremely prominent. Single Use-one trip lifting web slings are lightweight, easy to handle and load/unload, and can greatly improve the efficiency of material transfer. In a steel production workshop, time is equivalent to efficiency, and efficient material handling can accelerate the production rhythm. Moreover, the design of the hoisting bag enables it to be conveniently used in conjunction with various hoisting equipment. Whether it is a traveling crane, a forklift, or a crane, the hoisting work can be easily completed.

In terms of safety assurance, Single Use-one trip lifting web slings also perform excellently. They are made of special high-strength materials, which can bear a large weight and are not easy to be damaged. When hoisting steel materials, they greatly reduce the risk of safety accidents caused by the scattering of materials due to packaging damage, ensuring the personal safety of workers and the smooth progress of production.

Of course, there are many precautions when using Single Use-one trip lifting web slings. When selecting hoisting bags, the load-bearing capacity should be fully considered. Different specifications of Single Use-one trip lifting web slings have different load-bearing capacities. Steel enterprises must choose hoisting bags with appropriate load-bearing capacities according to the actual weight of the materials to be hoisted. If a hoisting bag with too small a load-bearing capacity is blindly selected, it may break during the hoisting process due to being unable to bear the weight of the materials, resulting in the falling of the materials. This will not only damage the materials but also possibly cause serious safety accidents.

When loading materials, it is necessary to ensure uniform distribution. If the materials are not loaded evenly, the hoisting bag will be unbalanced in force during the hoisting process, increasing the risk of tilting, overturning, or even breaking. In actual operation, professional loading equipment should be used as much as possible to ensure that the materials are evenly loaded into the hoisting bag, keeping the hoisting bag stable during hoisting.