Wristrong in-house Quality Control on Webbing slings

Pubdate: Apr 8,2021 Preview: 1,536

Regarding to in-house Quality Control on Webbing slings Of China Wristrong

Factory is always emphasizing quality control, while it's totally true but how many factories could make the real quality control into their daily production activities?

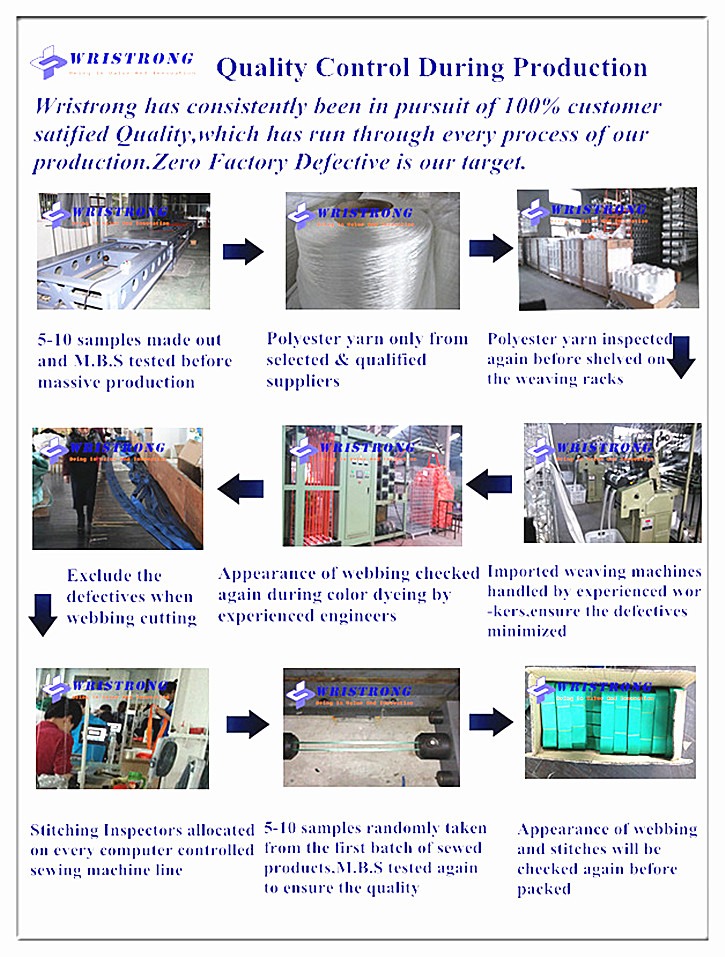

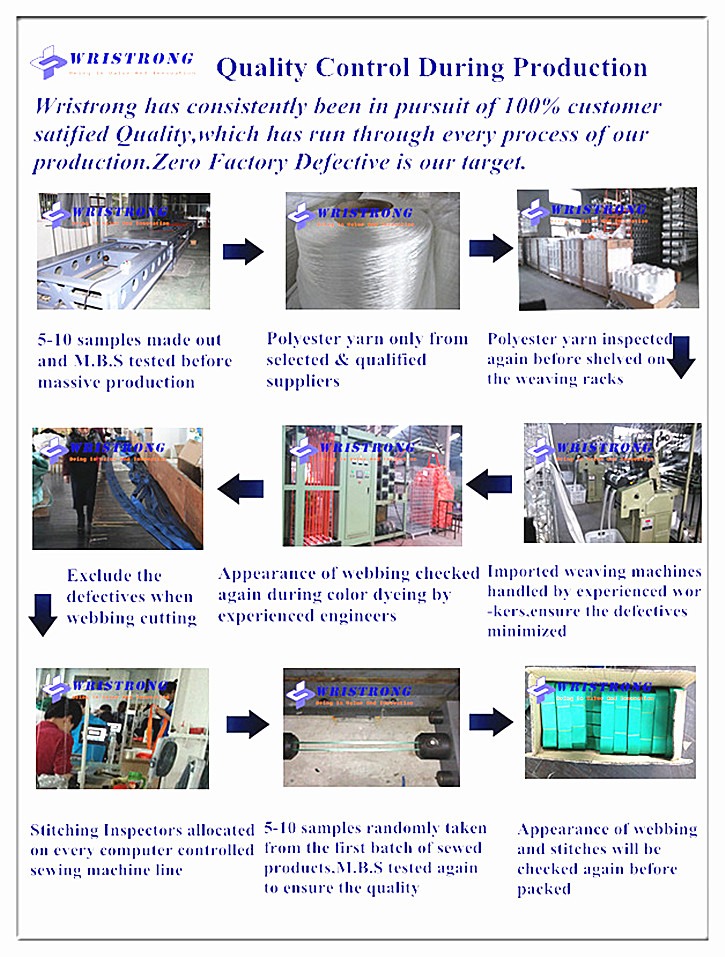

Our quality control start from materials selection. Take webbing sling as an example:

1.Polyester yarn selection: All of our polyester yarn are from big and famous domestic suppliers , which have been proven to be with excellent quality.

2. Weaving: The weaving worker will cut off the the line directly as soon as they find the inferior part.

3. Color dyeing: The color dyeing workers will sort out the webbing lines and make them orderly and neatly before dyeing.

During this process, the dyeing workers will mark the inferior parts with color tape(the tape color is obviously different from the color that the webbing will be dyed), or make obviously simple sewing . Of course these inferior parts will be cut off directly during next step.(Webbing line cutting)

4. Webbing line Cutting: There are always three cutting workers as a team. One of them just check before the webbing line is put onto heat-cutting desk. She/he will cut off the inferior parts by its small heat-cutting machine as soon as the problems are found. This step is very important as it will save a lot for the production.

5. Sewing: Currently we are widely used heavy-duty sewing machine, which will make our sewing works efficient and accurately. Even these is an error, the sewing works could adjust the program immediately. In addition, they will be a removable tag on every webbing sling, the tag will tell us who sew this item. Sewing workers will take responsible for any sewing problem, which will be found out in the next quality control steps. The sewing quality will decide how much they will be paid every month.

6.Inspection and finishing after sewing: This process is mainly check the sewing works, and remove the extra loose threads.

The inspection workers are all qualified with training certificates, which make them to make sure the sewing finishing will not affect the loading capacity of the webbing sling. And they will just take out the ones inferior parts that will affect the rate WLL and loading capacity directly.

7. Pre-packing: This is also a very important for the quality control. This process mainly sort out the webbing line into a certain shape for packing. The advantage is that workers could nearly see the every detail of the webbing line during this process. So if these is still any quality problem items, the workers will just select them out.

8: Packing: By the steps above, we can say 99%(we can't say 100%) of the goods will go without any quality problem and ready for packing. But even in this process , the packing workers will check very carefully in case there is any inferior one.

By these quality control processes above, we can say our inferior rate is less than 1% for the final finished products.

Above all, we never worry about any more waste on the materials. Today we waste materials, but tomorrow we earn customers' trust and long-term cooperation.

WRISTRONG QUALITY CONTROL ON LIFTING WEB SLING Illustration: